In the pursuit of sustainable energy solutions, lithium-ion batteries stand at the forefront of technological advancement. As the world gravitates towards electric vehicles and renewable energy storage, the longevity of these batteries becomes a matter of significant importance. The year 2024 heralds a new era where Artificial Intelligence (AI) and Quantum Analysis emerge as pivotal tools in predicting the lifespan of these energy powerhouses.

The intricate dance between energy efficiency and battery longevity is a complex one, fraught with variables that span from chemical composition to usage patterns. Traditional methods of lifespan prediction rely on empirical data and standardized tests, often falling short in real-world applications. Enter the realm of AI and quantum analysis – where the convergence of cutting-edge technology and theoretical physics promises a revolution in predictive accuracy.

AI, with its machine learning algorithms, has the power to sift through vast datasets, learning from each charge-discharge cycle, and detecting nuanced patterns that human analysis could easily overlook. Quantum analysis, on the other hand, delves into the subatomic interactions within the battery cells, offering a microscopic view of potential degradation pathways.

The fusion of these disciplines offers a beacon of hope for industries and consumers alike, seeking to optimize battery usage and plan for the future with greater certainty. As such, this article delves into the depth of these technologies, exploring their individual strengths and the synergetic potential they hold when combined.

Join us as we embark on this journey to demystify the technological advancements of 2024, offering a glimpse into the future of lithium-ion battery lifespan prediction with AI and quantum analysis. The insights provided herein are not merely speculative; they are rooted in current research, real-world applications, and a vision for a future where the full potential of battery technology can be harnessed in the most efficient manner.

Contents

Understanding Lithium-Ion Batteries

Before diving into the intricacies of lifespan prediction, it’s crucial to grasp the fundamentals of lithium-ion batteries. These devices are more than mere energy containers; they are complex chemical systems with properties that can change over time.

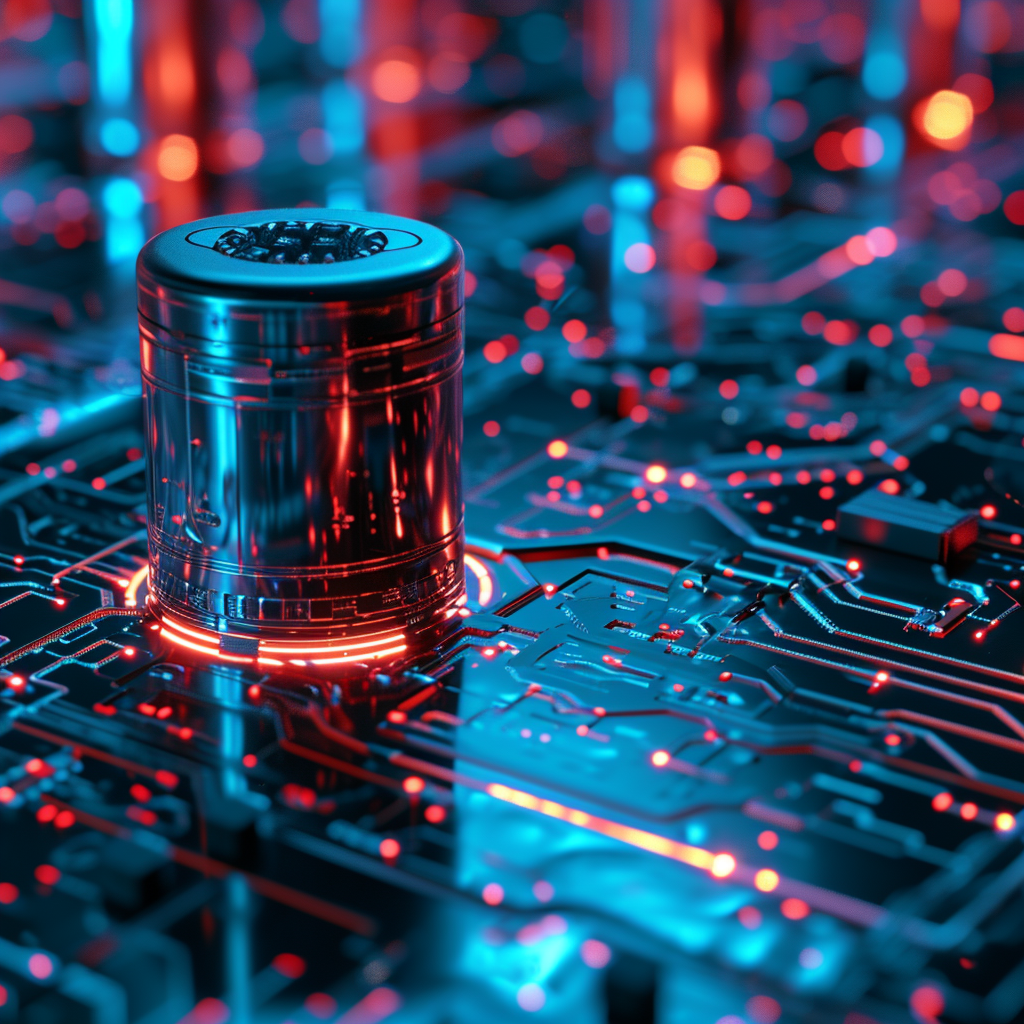

At their core, lithium-ion batteries consist of an anode, cathode, electrolyte, and separator. During discharge, lithium ions move from the anode to the cathode through the electrolyte, while electrons flow through an external circuit to provide power. This flow reverses during charging. The efficiency of these movements and the stability of the materials involved are paramount to the battery’s overall longevity.

However, each cycle of charging and discharging gradually wears on the battery’s internal components. Factors such as temperature, voltage, current, and even the battery’s design can lead to degradation mechanisms like solid electrolyte interphase (SEI) growth, lithium plating, and cathode dissolution.

Understanding these degradation pathways is essential for predicting a battery’s lifespan. Yet, this is where traditional methods often stumble, as they can’t account for the myriad of real-life conditions a battery faces. This is the void that AI and quantum analysis promise to fill, offering a more nuanced understanding of batteries that can lead to accurate lifespan predictions.

The Evolution of AI in Battery Technology

The journey of artificial intelligence in the realm of battery technology began with simple data analysis, but it has quickly evolved into a sophisticated predictive tool. AI algorithms can now learn from historical data, identify patterns, and even predict future outcomes with remarkable accuracy. This progression has been pivotal in transforming how we understand and anticipate the behavior of lithium-ion batteries.

Machine Learning and Predictive Maintenance

One of the most significant advancements is the use of machine learning for predictive maintenance. By analyzing past usage and performance data, AI can identify when a battery is likely to fail, allowing for proactive maintenance. This not only extends the life of the battery but also ensures reliability in critical applications like electric vehicles and grid storage.

Algorithmic Advancements

As algorithms grow more complex, they can consider a broader range of factors that affect battery life. These include charge rates, discharge patterns, and environmental conditions. Deep learning, a subset of AI, is particularly adept at working with unstructured data, finding hidden correlations that can provide early warning signs of battery degradation.

Real-time Monitoring and Adaptation

AI systems are now capable of real-time monitoring and adaptation. They can adjust charging protocols dynamically to optimize battery life based on immediate feedback from the battery’s condition. This level of responsiveness was unthinkable with earlier technologies and marks a significant step forward in battery management systems.

Quantum Analysis: A New Frontier

Quantum analysis represents a paradigm shift in our approach to understanding and predicting the behavior of lithium-ion batteries. This method leverages principles from quantum mechanics to model and analyze the interactions at the atomic and subatomic levels within the battery’s materials.

Quantum Chemistry and Material Science

Advancements in quantum chemistry have allowed scientists to simulate and study the electronic structure of materials used in lithium-ion batteries. These simulations can reveal how different materials will react under various conditions, providing insights into potential degradation pathways that could affect battery life.

Quantum Computing

The rise of quantum computing has opened new doors for battery research. Quantum computers can process complex simulations much faster than classical computers, enabling researchers to analyze vast amounts of data and intricate models that were previously too time-consuming or difficult to manage.

Predictive Power

By combining quantum mechanical models with statistical methods, researchers can now predict how a battery material will behave over time. This includes understanding how it will interact with the electrolyte, how stable it will be, and how external factors like temperature will affect its performance.

Data-Driven Insights: How AI Predicts Battery Lifespan

Artificial Intelligence thrives on data. The more it has, the more accurate its predictions can become. In the context of lithium-ion batteries, AI uses machine learning algorithms to analyze historical and real-time data to predict future performance and lifespan.

Historical Data Analysis

Machine learning algorithms start by examining vast amounts of historical data. This data may include charging and discharging cycles, temperature variations, load demands, and any other measurable factor that impacts battery health. By detecting patterns and anomalies within this data, the AI can construct a detailed model of battery behavior.

Real-time Performance Monitoring

The predictive capabilities of AI are further enhanced by real-time performance monitoring. Through continuous data acquisition from sensors embedded in battery systems, AI algorithms can detect deviations from expected behavior, suggesting the onset of battery degradation.

Predictive Modeling

With the insights gained from historical and real-time data, AI builds predictive models that estimate the remaining useful life of a battery. These models take into account various stress factors and usage patterns to provide a dynamic lifespan prediction that adjusts as new data comes in.

Enhanced Accuracy

The adoption of AI in lifespan prediction marks a significant improvement over traditional methods that often rely on static, one-size-fits-all models. AI’s dynamic approach allows for tailored predictions that reflect the unique conditions and usage patterns of each battery, leading to more accurate and reliable forecasts.

The Quantum Approach to Prediction

Quantum analysis takes us into the intricate world of atoms and electrons within the battery, providing a granular perspective of the processes that dictate battery life. This approach is rooted in the principles of quantum mechanics, which govern the behavior of matter at the smallest scales.

Unveiling Microscopic Interactions

Quantum analysis reveals the interactions between lithium ions, the electrolyte, and the active materials of the electrodes. It provides insights into the quantum states and energy levels of electrons, which are crucial for understanding the battery’s charge and discharge processes at a fundamental level.

Simulation of Degradation Mechanisms

The degradation of battery materials can be simulated using quantum mechanics, allowing scientists to visualize how different conditions affect the battery at an atomic level. These conditions include mechanical strain, temperature changes, and electrochemical reactions that can lead to capacity fade or other forms of degradation.

Quantum-Assisted Predictions

By simulating the behavior of every atom in the battery, quantum analysis can forecast how a battery will degrade under various use-case scenarios. When combined with AI, these quantum-assisted predictions can become more accurate, as AI algorithms refine the quantum models based on real-world data.

The Challenge of Scalability

Despite its potential, the quantum approach is computationally intensive and requires significant processing power, which can limit its scalability. Quantum computing, however, offers a solution by exponentially increasing the speed at which these calculations can be performed, thereby making quantum analysis more practical for widespread use.

Integrating AI and Quantum Analysis

The integration of AI and quantum analysis is the convergence of two powerful predictive domains, creating a comprehensive approach to understanding and forecasting battery lifespan. This integration leverages the strengths of both—AI’s pattern recognition and adaptability, with quantum analysis’s depth of understanding of material behaviors.

Synergistic Predictive Models

AI algorithms can incorporate quantum analysis data to create hybrid models that offer a more complete picture. These models can predict how a battery will age not just based on past performance, but also on the intrinsic properties of the battery materials that have been uncovered by quantum analysis.

Accelerated Material Discovery

The combination of AI and quantum analysis is revolutionizing material discovery and battery design. AI can quickly scan through potential materials identified by quantum simulations to find those with the best properties for long life and high performance, significantly speeding up the R&D process.

Real-World Application and Feedback

In practical applications, AI can use real-world usage data to continually refine the quantum models. This feedback loop ensures that the predictions remain accurate over time, accounting for unforeseen variables and usage patterns.

Challenges in Integration

Despite the clear benefits, integrating AI with quantum analysis is not without challenges. It requires the translation of quantum mechanical insights into a form that AI can process, as well as the development of algorithms that can handle the complexity of quantum data.

The Road Ahead

As we advance, the integration of AI and quantum analysis will likely become more streamlined, with advancements in quantum computing and machine learning algorithms driving the way forward. The potential for creating batteries with optimized lifespans and performance is vast and could significantly impact the energy sector, electric mobility, and beyond.

Case Studies in AI and Quantum Analysis

To illustrate the practical impact of integrating AI and quantum analysis in battery technology, let’s explore some case studies that highlight successes, challenges, and the lessons learned from real-world applications.

Automotive Industry Adoption

Case Study 1: Electric Vehicle (EV) Battery Optimization

A leading EV manufacturer integrates AI with quantum analysis to improve its battery lifespan prediction. The AI algorithm, trained on vast amounts of vehicle performance data, helps in forecasting battery degradation under various driving conditions. Meanwhile, quantum analysis provides insights into the optimal battery chemistry and structure for the manufacturer’s specific use case. The result is a more accurate prediction of battery lifespan, which improves warranty calculations and customer satisfaction.

Utility-Scale Storage Solutions

Case Study 2: Grid Energy Storage Management

An energy company employs AI to manage its utility-scale lithium-ion battery storage system. The AI uses predictive analysis to optimize charge/discharge cycles and minimize degradation, extending the system’s operational life. Quantum analysis contributes to this by enabling better selection of battery materials that can withstand the high-demand cycles of grid storage applications. The synergy between AI and quantum analysis leads to a more reliable grid and reduces the total cost of ownership of the storage system.

Challenges in Real-World Application

Case Study 3: High-Performance Computing for Quantum Simulations

A research institution faces challenges in applying quantum analysis due to computational limitations. While AI helps manage and interpret large datasets effectively, the quantum simulations require high-performance computing resources that are not readily available. The institution partners with a tech company to access quantum computing power, illustrating the need for collaboration in overcoming the technical hurdles of this approach.

Lessons Learned

From these case studies, several key points emerge:

- Collaboration Is Crucial: The complexity of integrating AI and quantum analysis often requires partnerships between industry, academia, and technology providers.

- Customization Is Key: AI models need to be tailored to specific applications and continuously updated with new data to maintain accuracy.

- Computational Requirements: There is a significant need for computational resources, which may be addressed with the advancement of quantum computing technologies.

- Material Innovation: Quantum analysis drives material innovation, but real-world testing is critical to validate these new materials.

As we move forward, these case studies will serve as benchmarks for the evolving landscape of battery technology, demonstrating the practical benefits and challenges of integrating AI and quantum analysis. The next chapter will discuss the future implications of these technologies and how they will continue to transform our approach to battery lifespan management.