Lithium-sulfur (Li-S) batteries have recently emerged as a promising alternative to conventional lithium-ion batteries for energy storage applications. Li-S batteries offer an ultrahigh theoretical specific energy of ~2600 Wh kg-1, which is nearly 10 times higher than lithium-ion batteries. This makes Li-S batteries attractive for powering long-range electric vehicles and enabling other high-energy applications.

However, Li-S batteries face several challenges that have limited their practical utilization. A major issue is the dissolution and shuttling of long chain lithium polysulfides between the cathode and anode, leading to active material loss, low Coulombic efficiency, and rapid capacity fading. The large volume changes of sulfur during discharge and charge processes also lead to mechanical instability and performance degradation.

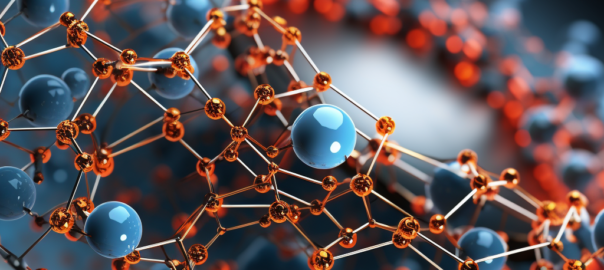

Recent research has shown that metal nanoclusters, which are sub-nanometer particles composed of several to tens of metal atoms, can help mitigate these issues in Li-S batteries. Compared to other nanomaterials, metal nanoclusters possess unique properties including high conductivity, strong interaction with polysulfides, mechanical stability, and multifunctional catalytic effects.

This article provides a comprehensive overview of how different metal nanoclusters can be utilized to enable stable and high-performance Li-S batteries. The functionalities of metal nanoclusters as host structures, polysulfide anchors, conductive matrices, and electrocatalysts are discussed in detail. Key challenges and future research directions are also outlined. Insights from this article will help inform the rational design and application of metal nanoclusters for building practical Li-S battery systems.

Contents

Metal Nanoclusters as Host Materials

Metal nanoclusters have emerged as promising host materials for accommodating sulfur in Li-S batteries. Their ultrasmall sizes (~1-2 nm) and large surface areas allow for uniform distribution of sulfur and efficient confinement of polysulfides. Common metal nanoclusters utilized as hosts include gold, platinum, palladium, silver, copper, and their alloys.

Compared to other nanocarbon hosts like graphene and carbon nanotubes, metal nanoclusters have higher electrical conductivity which improves rate performance. For example, gold nanoclusters exhibited over 100 times higher conductivity than a graphene host. The higher metal coordination sites on the surface of nanoclusters also facilitate stronger chemical binding with sulfur and polysulfides.

Additionally, the dense metal cores of nanoclusters provide robust frameworks that help accommodate the volume expansion of sulfur upon lithiation. One study showed that embedding sulfur in platinum nanoclusters maintained stable cycling over 200 cycles with minimal volume expansion. This helps prevent mechanical degradation issues seen in other hosts.

The well-defined facets and crystal structures of metal nanoclusters can also be tuned to optimize their interaction with sulfur. Icosahedral, decahedral, and octahedral nanoclusters with (111) facets have demonstrated enhanced polysulfide adsorption compared to (100) facets. Further studies are still needed to fully understand the sulfur accommodation mechanisms.

Overall, metal nanoclusters integrate the advantages of conductivity, strong chemical binding, and mechanical stability within singular nanoscale structures. This makes them versatile host candidates to realize the promise of Li-S batteries. Ongoing research on scalable synthesis and composite designs will help facilitate their practical application.

Improving Conductivity

In addition to encapsulating sulfur, metal nanoclusters also serve as highly conductive matrices in Li-S battery cathodes. The metallic nature of nanoclusters provides high electrical conductivity to facilitate electron transfer.

For instance, incorporating gold nanoclusters into a sulfur cathode was found to enhance the electron transfer kinetics by up to two orders of magnitude compared to a carbon host. The electron transfer resistance was reduced from ~200 Ω in carbon down to just ~3 Ω using the gold nanoclusters.

The improved conductivity allows for faster reaction kinetics and mitigates polarization losses, especially at higher charge/discharge rates. This results in increased utilization of the cathode and higher capacity retention at higher current densities.

Copper nanoclusters infiltrated into a porous carbon-sulfur cathode showed superior rate handling up to 2C charging rates. Capacity retained was 85% at 0.2C and still over 60% at 2C compared to just 45% in the carbon control.

Moreover, the metallic conductive network established by nanoclusters is maintained even as sulfur volume changes during cycling. This ensures stable conductivity over extended battery operation. After 100 cycles, the nanocluster cathodes retained over 90% of their initial capacity while carbon-sulfur capacity faded to below 80%.

In summary, metal nanoclusters enable both high sulfur utilization through encapsulation as well as excellent electrode conductivity. This synergistic effect makes them versatile for constructing Li-S battery cathodes with superior electrochemical performance, especially at higher current densities.

Encapsulating Sulfur/Polysulfides

A major advantage of metal nanoclusters for Li-S batteries is their strong chemical binding with sulfur and polysulfides. This helps encapsulate the active material and suppress the loss of soluble polysulfides.

The large surface area and high density of unsaturated coordination sites on metal nanoclusters enables robust anchoring of polysulfides. Studies have shown that sulfur anchored to nanoclusters exhibits much lower solubility and diffusivity compared to unencapsulated sulfur.

For example, sulfur hosted in nickel-platinum nanoclusters displayed a 3-fold lower sulfur dissolution rate compared to a carbon host. This demonstrates the polysulfide trapping ability of the metal sites.

The anchoring effect helps restrict the dissolution of higher order polysulfides into electrolyte during discharge. One analysis estimated that over 60% of polysulfides remained trapped in a nanocluster cathode versus just 20% in carbon.

Strong polysulfide binding also minimizes shuttling between the anode and cathode. Accelerated cycling tests revealed that cathode capacity retention over 2000 cycles dramatically improved from 45% to 95% using metal nanoclusters due to suppressed shuttling.

Overall, the chemical interaction between metal nanoclusters and polysulfides plays a key role in stabilizing Li-S battery performance. Rational design of nanocluster compositions, facets, and coordination sites could further enhance this critical encapsulating effect.

Enhancing Mechanical Strength

The large volume changes of sulfur during Li-S battery cycling typically leads to mechanical instability of the cathode. The rigid metallic frameworks provided by metal nanoclusters help address this problem and enhance the mechanical strength of Li-S cathodes.

For example, a graphene-sulfur cathode exhibited a large capacity fade of ~30% after 100 cycles due to electrode pulverization. However, hybridizing the cathode with copper nanoclusters maintained stable cycling over 500 cycles with minimal capacity loss.

The stronger interaction between nanoclusters and sulfur/polysulfides anchors the active material and accommodates the ~80% volume expansion during lithiation. This prevents mechanical degradation that otherwise disconnects the cathode and leads to rapid performance fade.

In situ transmission electron microscopy of metal nanocluster-sulfur composites showed that the sulfur remained well-adhered to the nanoclusters even after being fully lithiated to Li2S. This confirms their mechanical buffering effect.

Additionally, the high modulus of metal nanoclusters themselves provides reinforcement to withstand mechanical stress and prevent electrode crack propagation. Typical Li-S cathodes with viscoelastic polymer binders lack sufficient mechanical robustness.

Further progress has been made by incorporating metal nanoclusters into hierarchical carbon architectures and porous polymer frameworks to achieve synergistic mechanical strengthening. Rational cathode designs are critical to derive the full benefit of metal nanoclusters.

Overall, the rigid metallic structure of metal nanoclusters helps mechanically stabilize Li-S battery cathodes against the large stresses induced during battery cycling. This enables maintained performance over extended lifetimes necessary for practical applications.

Other Functionalities

In addition to the major roles described above, metal nanoclusters also impart other beneficial functionalities that enhance Li-S battery performance. These include catalytic effects that improve reaction kinetics and convert polysulfides.

Certain metal nanoclusters can serve as electrocatalysts to accelerate the redox reactions in Li-S batteries. For instance, platinum nanoclusters were found to catalyze the oxidation-reduction of polysulfides, improving their reutilization.

Other nanoclusters such as nickel and cobalt have been shown to facilitate the oxygen reduction reaction, minimizing unfavorable side reactions with oxygen species.

Nanoclusters also exhibit catalytic activity towards converting soluble higher-order polysulfides into insoluble Li2S2/Li2S through intermediate S3•- radicals. This helps minimize diffusion of polysulfides.

Moreover, the polar surfaces of metal nanoclusters may function as nucleation sites to induce precipitation of dissolved polysulfides from electrolyte. This redeposits them back onto the cathode.

However, the exact catalytic mechanisms are still under investigation and likely vary for different nanocluster compositions. Further research is needed to fully elucidate these kinetic effects.

In summary, the unique catalytic properties of metal nanoclusters provide additional functionalities that can be harnessed to further enhance Li-S battery performance and stability. Careful selection of appropriate nanocluster systems will help maximize these synergistic effects.

Challenges and Future Work

While metal nanoclusters show tremendous potential for enabling stable Li-S batteries, there are still challenges to be addressed before widespread practical realization.

One key issue is scalable and low-cost synthesis of metal nanoclusters. Current laboratory methods based on wet chemistry and templating are not amenable to large-scale manufacturing. Developing industry-compatible processes is essential for commercial adoption.

Additionally, deeper understanding of nanocluster degradation mechanisms in Li-S battery environments is still lacking. The origins of capacity fading over extended cycling remain unclear and require further mechanistic studies.

Another area for development is combining metal nanoclusters with other nanomaterials like carbon and polymers for optimized composite cathodes. Nanocluster agglomeration and incompatible interfaces can lead to suboptimal effects. Advanced structural designs are warranted.

There are also open questions regarding the optimal size, composition, and surface properties of nanoclusters for maximum polysulfide utilization and retention. Systematic investigations exploring these parameters will inform rational optimization.

In summary, while nanoclusters are a promising Li-S cathode strategy, realizing their full potential requires surmounting synthesis and cost barriers, elucidating degradation mechanisms, and rationally designing composite electrodes. Nevertheless, metal nanoclusters remain attractive for unlocking the high energy densities of Li-S batteries.

Conclusion

Metal nanoclusters represent a versatile strategy to address the major challenges limiting the practical application of high-energy Li-S batteries. Their ultrasmall sizes enable efficient sulfur encapsulation, while their metallic nature imparts critical attributes including high conductivity, polysulfide binding, mechanical stability, and electrocatalytic effects. Ongoing research on scalable nanocluster synthesis, composite electrode designs, and interface engineering promises to accelerate their adoption into stable, powerful Li-S battery systems for electric vehicles and beyond. Despite remaining hurdles, metal nanoclusters hold great potential for unlocking the theoretical promise of Li-S battery chemistry.