The technological advancements of the 21st century have spurred a massive shift towards renewable energy sources and energy-efficient devices. Central to this transformation is the lithium-ion battery, a compact powerhouse that fuels everything from smartphones to electric vehicles. However, the extraction of lithium, a key component of these batteries, presents significant environmental challenges. In our quest for sustainable solutions, one surprising contender has emerged: microalgae.

Microalgae, simple, often unicellular organisms, have shown promise in the green extraction of lithium. They offer an environmentally friendly alternative to traditional methods, which are not only energy-intensive but also result in substantial CO2 emissions.

In this article, we delve into the innovative world of lithium extraction with microalgae. We’ll explore the growing demand for lithium, the drawbacks of conventional extraction methods, and how microalgae can contribute to a more sustainable future. We’ll examine the science behind this green extraction process, its advantages, and the existing research supporting its efficacy. Furthermore, we’ll also look at the challenges this method faces and its future prospects.

This exploration is not just about lithium extraction. It’s about our collective journey towards sustainability. It’s about finding innovative, green solutions that respect our planet’s limitations, while also catering to our technological needs. It’s about envisioning a future where technology and nature work hand in hand for a healthier world.

Contents

The Growing Demand for Lithium

The lithium-ion battery has revolutionized modern technology, driving the growth of various industries and shaping the way we live and work. As a key component of these batteries, lithium has become a vital resource in our era of digitalization and renewable energy.

The electric vehicle (EV) market, in particular, relies heavily on lithium-ion batteries. The International Energy Agency (IEA) reports that the global EV fleet, including cars, buses, vans, and heavy trucks, reached 10 million in 2020, up from just 17,000 a decade earlier1. Consequently, lithium demand is expected to triple by 2025.

Moreover, lithium is an essential element in renewable energy storage systems. As the world seeks to reduce its dependence on fossil fuels, the demand for efficient, high-capacity energy storage is rising, further driving the need for lithium.

This increasing demand, while indicative of technological advancement and environmental consciousness, also poses considerable environmental challenges. Traditional lithium extraction methods have high ecological costs, affecting water sources, soil quality, and air purity.

Traditional Lithium Extraction: A Brief Overview

Lithium, despite being the 25th most abundant element on Earth, is not widely distributed. It primarily exists in hard rock minerals and saline brines. These sources lead us to the two primary methods of lithium extraction: hard rock mining and brine evaporation.

Hard rock mining involves extracting lithium from spodumene, a mineral found in pegmatite rock formations. This process is energy-intensive, requiring significant amounts of electricity and fuel. It also results in substantial waste material, which can contaminate nearby land and water sources.

On the other hand, lithium brine extraction involves pumping saline groundwater from underground reservoirs to the surface. The brine is left to evaporate in large pools, leaving behind lithium salts. This process, albeit less energy-intensive than hard rock mining, is slow, taking up to 18 months to complete. It also uses massive quantities of water, a critical concern in the arid regions where lithium brine is often found.

These traditional methods of lithium extraction, while effective, present significant environmental challenges. They consume large amounts of energy and water, contribute to pollution, and can have detrimental effects on local ecosystems.

Microalgae: An Eco-friendly Alternative

Microalgae, these tiny powerhouses of nature, have been on Earth for billions of years. They have adapted to a wide range of environments and have developed an ability to accumulate and store various minerals, including lithium.

Microalgae-based lithium extraction is a bioleaching process. Bioleaching, in its simplest form, is the extraction of metals from their ores through the use of living organisms. In this case, microalgae are the living organisms used to extract lithium from lithium-containing solutions.

The primary advantage of this method is its eco-friendliness. Unlike traditional extraction methods, microalgae-based lithium extraction doesn’t involve large-scale land disruption or significant energy and water consumption. Instead, it harnesses the natural abilities of microalgae, offering a green and sustainable alternative.

Microalgae not only reduce the environmental footprint of lithium extraction but also contribute to carbon sequestration. They absorb CO2 during photosynthesis, thereby mitigating greenhouse gas emissions. This double benefit – green lithium extraction and carbon capture – underscores the potential of microalgae in our quest for environmental sustainability.

The Science Behind Lithium Extraction with Microalgae

The process of lithium extraction using microalgae is a fascinating blend of biology and chemistry. It’s a bioleaching process where microalgae, through metabolic activities, extract lithium from aqueous solutions.

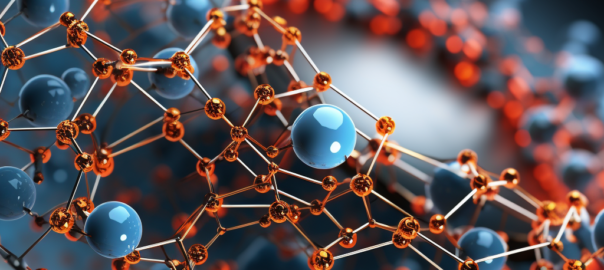

Microalgae possess cell walls rich in polysaccharides and proteins that can selectively bind to lithium ions1. This interaction is facilitated by the nature of lithium ions. Lithium, being the lightest alkali metal, possesses a small ionic radius and high charge density, allowing it to interact effectively with the functional groups of the microalgal cell walls.

The process begins with the microalgae being exposed to a lithium-containing solution. The lithium ions in the solution interact with the microalgal cell walls, adhering to them in a process known as biosorption. Post biosorption, the microalgae are separated from the solution, effectively removing the lithium ions.

The lithium can then be recovered from the microalgae through a process known as desorption. This usually involves treating the lithium-loaded microalgae with a solution that encourages the lithium ions to detach from the microalgal cell walls.

This biological process of lithium extraction is not only environmentally friendly but also highly selective and efficient. It offers a promising alternative to conventional lithium extraction methods, but its real-world application isn’t without challenges.

Advantages of Microalgae Lithium Extraction

The use of microalgae in lithium extraction presents several advantages over traditional methods, making it a promising approach for sustainable lithium production. Here, we explore some of these benefits.

1. Environmental Friendliness:

The most significant advantage of microalgae-based lithium extraction lies in its eco-friendly nature. It does not involve large-scale land disruption, high energy consumption, or significant water usage, unlike traditional extraction methods. This makes it a green alternative that aligns with global sustainability goals.

2. Carbon Capture:

Microalgae are well known for their ability to capture and sequester carbon dioxide. This additional benefit turns the lithium extraction process into a dual-purpose operation, contributing to the reduction of greenhouse gas emissions.

3. Selectivity:

Microalgae extraction methods can be significantly selective, effectively separating lithium from other metal ions present in the solution1. This is especially beneficial when dealing with complex brine compositions.

4. Scalability:

Microalgae cultivation is highly scalable. They can grow in a variety of environments, from open ponds to bioreactors, making large-scale operations feasible.

Existing Research & Case Studies

The potential of microalgae-based lithium extraction has caught the attention of researchers worldwide. While still in the early stages, several studies have yielded promising results.

One of the pioneering studies in this field was conducted by Borowitzka and Moheimani in 2013. They explored the ability of microalgae to accumulate lithium from brine, and the results were promising, with several microalgal strains showing significant lithium uptake.

In a more recent study, Ren et al. (2021) demonstrated the potential of a particular microalga, Chlorella vulgaris, to absorb lithium from lithium-containing solutions2. This study underscored the potential of microalgae as biological tools for lithium recovery from wastewater.

Moreover, several companies are already capitalizing on this potential. For instance, PhycoTech, a Michigan-based company, has patented a process for extracting lithium from water using microalgae

Challenges and Future Prospects

While the potential for microalgae in lithium extraction is promising, the method is not without its challenges. Here are a few of the major hurdles to overcome:

1. Efficiency: While microalgae can bioaccumulate lithium, the overall efficiency of extraction and recovery needs to be improved for the process to be commercially viable.

2. Scalability: Despite the scalability of microalgae cultivation, challenges persist in scaling the extraction process. Large-scale operations will require significant advancements in bioreactor design and process optimization.

3. Desorption: The desorption process, where lithium is recovered from the microalgae, is a critical step that needs further research and development. It’s crucial to optimize this step to ensure maximum lithium recovery.

4. Regulation: Regulatory frameworks for bioleaching processes are still in their infancy. As with any novel technology, creating suitable regulations that ensure safety and sustainability will be a significant challenge.

Despite these challenges, the future of microalgae-based lithium extraction looks promising. As we strive for more sustainable practices in our quest to meet increasing lithium demand, this bio-based approach offers a viable and eco-friendly alternative.