Lithium metal cells are an essential component of many modern batteries, powering devices ranging from smartphones to electric vehicles. While their efficiency and capacity have improved significantly in recent years, researchers continue to seek ways to enhance their performance. One promising avenue of exploration involves using advanced 3D imaging techniques to gain insights into the inner workings of these cells. This article delves into the fascinating world of lithium metal cells, exploring their structure, how they function, and the ways in which 3D imaging is transforming our understanding of this critical technology.

Section 1: The Importance of Lithium Metal Cells

1.1 The rise of lithium metal cells

Lithium metal cells have experienced rapid growth in popularity due to their high energy density and ability to support a wide range of applications. These cells can store more energy per unit of weight compared to other common battery chemistries, making them an attractive option for portable electronics and electric vehicles.

1.2 Applications of lithium metal cells

Lithium metal cells are found in numerous devices, including smartphones, laptops, power tools, and electric vehicles. Their high energy density and lightweight design make them ideal for applications where space and weight are critical factors. As demand for sustainable energy sources grows, lithium metal cells are also playing an increasingly important role in renewable energy storage systems.

1.3 The need for improved performance

Despite their many advantages, lithium metal cells still face several challenges, including limited cycle life, safety concerns, and performance degradation over time. To address these issues, researchers are exploring innovative ways to optimize the design, materials, and manufacturing processes of lithium metal cells, ultimately aiming to enhance their performance and safety.

Section 2: The Structure and Function of Lithium Metal Cells

2.1 Anatomy of a lithium metal cell

A typical lithium metal cell consists of three main components: a lithium metal anode, a cathode made from a lithium-containing compound, and an electrolyte that facilitates ion transport between the anode and cathode. The cell is typically encased in a protective housing to prevent external contamination and ensure safety.

2.2 The electrochemical process

When a lithium metal cell is discharging, lithium ions in the anode migrate through the electrolyte and are captured by the cathode, releasing energy in the process. During charging, an external voltage is applied, causing lithium ions to move from the cathode back to the anode, where they are stored for future use.

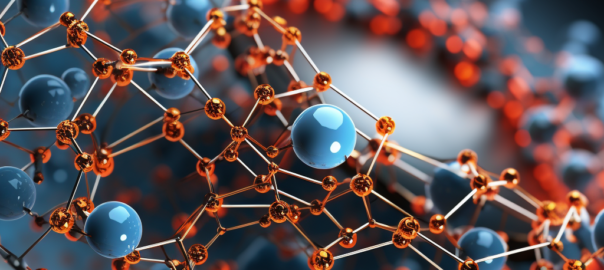

2.3 The challenge of dendrite formation

One major challenge facing lithium metal cells is the formation of dendrites, which are needle-like structures that grow on the anode during charging. Dendrites can penetrate the separator between the anode and cathode, causing a short circuit and potentially leading to thermal runaway and cell failure. Researchers are actively investigating ways to mitigate dendrite growth and improve the safety of lithium metal cells.

Section 3: An Introduction to 3D Imaging Techniques

3.1 Overview of 3D imaging methods

Several 3D imaging techniques are available for investigating lithium metal cells, including X-ray computed tomography (CT), focused ion beam scanning electron microscopy (FIB-SEM), and magnetic resonance imaging (MRI). Each method offers unique advantages and limitations, with researchers selecting the most suitable technique based on the specific goals of their study.

3.2 Advantages of 3D imaging in battery research

3D imaging provides valuable insights into the internal structure and behavior of lithium metal cells, enabling researchers to visualize the distribution of materials, monitor the growth of dendrites,

and evaluate the performance of various cell components. By offering a non-destructive means of investigating these cells, 3D imaging allows for real-time monitoring of cell behavior under various operating conditions.

3.3 Challenges and limitations of current 3D imaging techniques

Despite their advantages, 3D imaging techniques also face some challenges. High-resolution imaging often requires long acquisition times, which can limit the ability to capture dynamic processes. Additionally, the complex nature of the data obtained from 3D imaging can be challenging to analyze and interpret.

Section 4: Insights from 3D Imaging on Lithium Metal Cells

4.1 Visualization of internal structures

Using 3D imaging, researchers can visualize the internal structure of lithium metal cells, including the distribution of active materials within the electrodes, the porosity of the separator, and the overall cell architecture. These insights can help identify design flaws and inform the development of improved cell designs and manufacturing processes.

4.2 Dendrite detection and analysis

One of the most significant contributions of 3D imaging to lithium metal cell research is the ability to monitor dendrite growth in real-time. This information is invaluable in understanding the factors that contribute to dendrite formation and identifying strategies to mitigate their growth, ultimately improving the safety and performance of lithium metal cells.

4.3 Evaluation of electrolyte distribution

3D imaging techniques can also reveal the distribution of electrolytes within a lithium metal cell, which plays a crucial role in ion transport and overall cell performance. By analyzing electrolyte distribution, researchers can optimize the design and composition of electrolytes to enhance cell performance.

4.4 Identification of manufacturing defects

Manufacturing defects, such as uneven electrode coatings or misaligned separators, can adversely impact the performance and safety of lithium metal cells. 3D imaging enables the detection of such defects, allowing manufacturers to refine their production processes and improve the quality of their products.

Section 5: How 3D Imaging is Driving Innovation in Lithium Metal Cell Technology

5.1 Improving cell design and manufacturing

By providing detailed insights into the internal structure and behavior of lithium metal cells, 3D imaging is driving innovations in cell design and manufacturing. Researchers can use these insights to develop more efficient and robust cells, enabling improved performance and longer service life.

5.2 Developing advanced materials and electrolytes

3D imaging is also contributing to the development of advanced materials and electrolytes for lithium metal cells. By studying the behavior of these materials under various conditions, researchers can identify novel compounds and formulations that enhance cell performance and mitigate the challenges associated with dendrite growth.

5.3 Enhancing safety and mitigating risks

Lastly, the insights gained from 3D imaging are helping to improve the safety of lithium metal cells. By better understanding the factors that contribute to dendrite formation and cell failure, researchers can develop strategies to prevent these issues, reducing the risk of thermal runaway and other safety concerns.

Conclusion

Lithium metal cells have become a cornerstone of modern energy storage solutions, yet their full potential remains untapped. By employing cutting-edge 3D imaging techniques, researchers are gaining unprecedented insights into these cells’ inner workings, paving the way for improvements in efficiency, capacity, and safety. As this technology continues to advance, the potential applications of lithium metal cells are poised to expand, transforming industries and improving the lives of people worldwide.