Server power supplies are crucial components of any network. They provide the energy needed to run servers, which are the workhorses of modern information systems. However, there can be instances when it becomes necessary or advantageous to convert these server power supplies. This could be due to reasons like repurposing old server hardware, saving costs, or meeting unique power requirements that conventional power solutions cannot satisfy.

While server power supply conversion may seem daunting, with a careful approach and a keen understanding of the hardware, it’s a process that can be executed with precision. In this comprehensive guide, we aim to demystify the process and provide you with a step-by-step guide to converting server power supplies.

Contents

- 1 II. Understanding Server Power Supplies

- 2 III. When and Why to Convert Server Power Supplies

- 3 IV. How to Safely Handle Server Power Supplies

- 4 . Step by Step Guide to Convert Server Power Supplies

- 5 VI. Troubleshooting Common Conversion Issues

- 6 VII. Case Studies on Server Power Supply Conversion

- 7 VIII. Conclusion

II. Understanding Server Power Supplies

A. Types of Server Power Supplies

There are several types of server power supplies, but the most commonly used are the AC and DC power supplies.

| Type | Description |

|---|---|

| AC Power Supplies | Alternating Current (AC) power supplies are the most common types found in most servers. They convert AC voltage from the main power source to the direct current (DC) required by the computer components. |

| DC Power Supplies | Direct Current (DC) power supplies are less common and typically used in specific applications. They receive DC voltage input and regulate it to the required levels for the server components. |

B. Technical Specifications of Server Power Supplies

When working with server power supplies, it’s crucial to understand their technical specifications. This includes the input voltage, output voltage, current rating, efficiency, and more. Understanding these specifications will help you in the conversion process.

| Specification | Description |

|---|---|

| Input Voltage | The voltage that the power supply requires from the power source. |

| Output Voltage | The voltage that the power supply provides to the computer components. |

| Current Rating | The maximum current that the power supply can provide. |

| Efficiency | The percentage of input power that is effectively converted into output power. |

C. Server Power Supply vs Regular Power Supply

Server power supplies are specifically designed to meet the rigorous demands of server environments. They often have higher efficiency ratings, better cooling mechanisms, and more robust designs than regular power supplies. They are also typically more expensive due to these advanced features. However, for certain applications, it can be more cost-effective and beneficial to convert server power supplies instead of purchasing new ones.

III. When and Why to Convert Server Power Supplies

A. Scenarios for Conversion

Several situations might necessitate the conversion of server power supplies. Below are some of the most common:

- Repurposing Old Server Hardware: Often, companies upgrade their servers, leaving old but functional hardware behind. These power supplies can be converted for various purposes such as powering 3D printers, amateur radio equipment, or other high power electronic devices.

- Cost-Saving: Server power supplies are generally more efficient and reliable than consumer-grade power supplies, and you can often find used ones at a fraction of the price of new, standard power supplies.

- Custom Power Requirements: Sometimes, you may need a power supply with specific characteristics that are not readily available in the market. In such cases, converting a server power supply can be a great solution.

| Scenarios | Explanation |

|---|---|

| Repurposing Old Server Hardware | To utilize functional hardware left behind after server upgrades. |

| Cost-Saving | Server power supplies are generally more efficient and cheaper than new consumer-grade power supplies. |

| Custom Power Requirements | When there’s a need for power supplies with specific characteristics not readily available. |

B. Benefits of Conversion

The conversion of server power supplies comes with several benefits:

- Efficiency: Server power supplies are designed for maximum efficiency, which can lead to significant energy savings over time.

- Reliability: Server components, including power supplies, are made to operate 24/7 for many years, making them exceptionally reliable.

- Cost-effective: Especially when utilizing old or second-hand server power supplies, the cost of conversion can be considerably less than purchasing new equipment.

| Benefits | Explanation |

|---|---|

| Efficiency | Server power supplies are designed for maximum efficiency leading to energy savings. |

| Reliability | Server components are made to operate 24/7 making them exceptionally reliable. |

| Cost-effective | Conversion of old or second-hand server power supplies is less costly than new equipment. |

IV. How to Safely Handle Server Power Supplies

A. Precautions and Safety Measures

Safety is paramount when working with any electrical equipment, including server power supplies. Here are some key safety measures:

- Unplug the Power Supply: Always ensure the power supply is unplugged before you start working on it.

- Avoid Physical Contact with Internal Components: Do not touch any internal components with bare hands, especially when the power supply is plugged in.

- Use Protective Gear: Always wear protective gear, including gloves and eye protection, when working with power supplies.

- Work in a Well-Ventilated Area: Power supplies can get hot, so make sure your workspace is well-ventilated.

- Have a Fire Extinguisher Handy: This is a necessary safety measure when working with any electrical equipment.

B. Required Tools and Equipment

Different conversion projects may require different tools. However, some of the most common tools required include:

- Multimeter: To measure voltage and current.

- Soldering Iron: For any required soldering.

- Wire Cutters/Strippers: To cut and strip wires.

- Screwdrivers: To open the power supply case.

- Heat Shrink Tubing and Lighter: To insulate any exposed connections.

| Tool | Use |

|---|---|

| Multimeter | To measure voltage and current. |

| Soldering Iron | For any required soldering. |

| Wire Cutters/Strippers | To cut and strip wires. |

| Screwdrivers | To open the power supply case. |

| Heat Shrink Tubing and Lighter | To insulate any exposed connections. |

. Step by Step Guide to Convert Server Power Supplies

Before proceeding, ensure that you have the necessary safety measures in place and that your work area is properly prepared.

A. Preparation Steps

- Understanding the Power Supply Specifications: Take note of the specifications of the power supply, including input and output voltage, current rating, and efficiency.

- Gathering the Necessary Tools and Materials: Based on the specific power supply and your conversion needs, gather the necessary tools and materials.

B. Detailed Conversion Process

- Open the Power Supply: Using the screwdriver, carefully open the power supply. Be careful not to touch any internal components to avoid electrical shock.

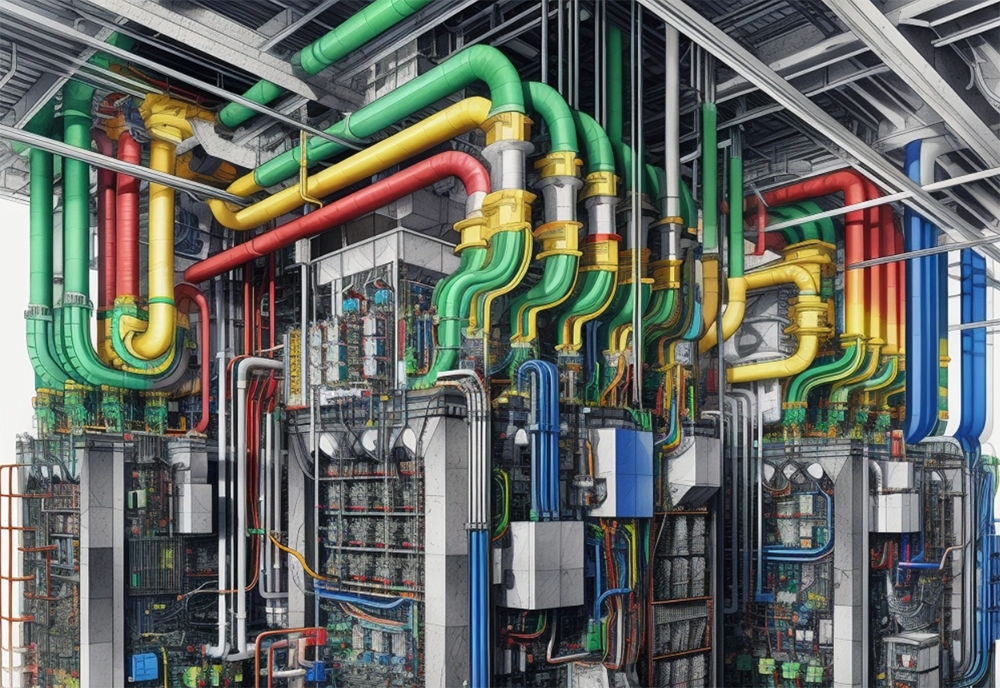

- Identify the Output Wires: Locate the output wires. These are usually color-coded: yellow for 12V, red for 5V, and black for ground.

- Prepare the Output Wires: Using the wire cutters and strippers, cut and strip the output wires to the desired length.

- Solder the Output Wires to the Desired Output Connector: If necessary, solder the output wires to the connector that matches your needs. For example, for a 12V output, solder the yellow and black wires to a suitable 12V connector.

- Insulate the Connections: Using heat shrink tubing and a lighter, insulate the connections to prevent short circuits.

- Test the Converted Power Supply: Use the multimeter to confirm that the converted power supply is outputting the correct voltage and current.

- Close the Power Supply: After confirming that everything is working correctly, carefully close the power supply.

C. Post-conversion Steps

- Run a Full Load Test: After the initial test, run a full load test to confirm that the converted power supply can handle the maximum current for an extended period.

- Install the Converted Power Supply: Now, you can install the converted power supply in its intended application.

| Step | Description |

|---|---|

| Open the Power Supply | Open the power supply casing without touching any internal components. |

| Identify the Output Wires | Locate the output wires which are usually color-coded. |

| Prepare the Output Wires | Cut and strip the output wires to the desired length. |

| Solder the Output Wires | Solder the output wires to the connector that matches your needs. |

| Insulate the Connections | Insulate the connections using heat shrink tubing. |

| Test the Converted Power Supply | Use a multimeter to test the output voltage and current. |

| Close the Power Supply | After testing, close the power supply. |

| Run a Full Load Test | Run a full load test to confirm stability. |

| Install the Converted Power Supply | Install the converted power supply in its intended application. |

VI. Troubleshooting Common Conversion Issues

No matter how carefully you proceed, you may run into a few hitches along the way. Here are common issues you may encounter during the conversion of server power supplies, and suggested solutions.

A. Common Problems and Solutions

| Problem | Solution |

|---|---|

| Power Supply Does Not Start | Many server power supplies need a load on their output to start. Try connecting a small load like a 10-ohm resistor across the output. |

| Incorrect Output Voltage | Ensure you have identified the correct output wires. Refer to the power supply documentation or look for color-coding. |

| Power Supply Shuts Down Under Load | This could be a sign that the power supply is overloaded. Ensure that your load does not exceed the power supply’s rated current. |

| Power Supply Overheats | Ensure adequate ventilation. If the problem persists, the power supply may be faulty. |

B. Tips for Successful Conversion

- Always refer to the power supply’s documentation or seek professional advice if unsure.

- Regularly test the power supply during the conversion process.

- Use quality tools and materials to ensure a safe and reliable conversion.

VII. Case Studies on Server Power Supply Conversion

A. Case Study 1

In an example of successful server power supply conversion, a hobbyist running a 3D printing workshop managed to repurpose old server power supplies to power his array of 3D printers. He documented his process, which largely aligns with the steps described in this guide. The conversion allowed him to save on the cost of buying new power supplies and to repurpose otherwise obsolete server components.

B. Case Study 2

Another interesting case involves a radio amateur who needed a reliable and affordable power supply for his radio equipment. He converted a server power supply to meet his requirements. He particularly praised the reliability and efficiency of the converted power supply, which surpassed those of the consumer-grade power supplies he previously used.

VIII. Conclusion

Server power supply conversion can be a practical, cost-effective, and environmentally-friendly solution in several scenarios. Whether you’re repurposing old server hardware, aiming to save costs, or need a custom power supply for a unique application, conversion of server power supplies can be an ideal solution. The process might seem daunting at first, but with the right approach and careful attention to detail, you can successfully convert a server power supply to meet your specific needs.

In the future, as we continue to strive for efficiency and sustainability in technology, the practice of converting server power supplies may become even more common. For anyone with an interest in electronics or hardware, understanding this process and its benefits can be an invaluable skill.

Remember, safety is paramount when working with electrical components. Always take necessary precautions and don’t hesitate to seek professional help if you encounter issues beyond your expertise.